Tel

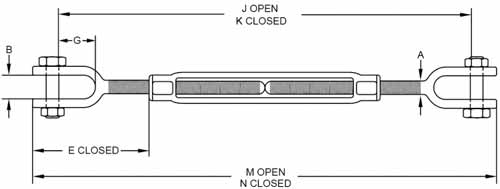

Turnbuckle Jaw & Jaw US Type.

Turnbuckle Jaw & Jaw US Type is recommended for straight or in-line pull only, commonly used for adjusting the tension or length of wire rope, aircraft cable, tie rod and other tensioning systems.

It consists of two threaded sections, each end screws into a metal frame, one with a left-hand thread and the other with a right-hand thread.

The tension can be adjusted by rotating the frame, which causes both sides bolts to be screwed in or out, without twisting attached rope or cable.

Same size with different end fittings are available: Hook & Hook, Eye & Eye, Hook & Eye, Jaw & Eye etc.

| Technical Notes | US Federal Specification |

| Material | Superior Carbon Steel |

| Safety Factor | Proof tested to 2 x WLL and Minimum Break Force is 5 x WLL. |

| Processing | Drop Forged + Machining + Quenched and Tempered |

| Surface Finished | Electric Galvanized / Hot Dipped Galvanized |

| Thread Dia & Take Up(in) | 1/4×4 , 5/16×4-1/2 , 3/8×6 , 1/2×6 , 1/2×9 , 1/2×12 , 5/8×6 , 5/8×9 , 5/8×12 , 3/4×6 , 3/4×9 , 3/4×12 , 3/4×18 , 7/8×12 , 7/8×18 , 1×6 , 1×12 , 1×18 , 1×24 , 1-1/4×12 , 1-1/4×18 , 1-1/4×24 , 1-1/2×12 , 1-1/2×18 , 1-1/2×24 , 1-3/4×18 , 1-3/4×24 , 2×24 , 2-1/2×24 , 2-3/4×24 |

| Origin | China |

| Thread Dia & Take Up | W.L.L. | U.W | Dimensions | ||||||

| B | E | G | J | K | M | N | |||

| lbs | lbs/pc | Closed | Open | Closed | Open | Closed | |||

| 1/4×4 | 500 | 0.37 | 0.45 | 1.66 | 0.64 | 11.19 | 7.19 | 12.18 | 8.18 |

| 5/16×4-1/2 | 800 | 0.56 | 0.5 | 2.02 | 0.87 | 13.07 | 8.57 | 14.12 | 9.62 |

| 3/8×6 | 1200 | 0.85 | 0.53 | 2.11 | 0.85 | 16.25 | 10.25 | 17.5 | 11.5 |

| 1/2×6 | 2200 | 1.82 | 0.64 | 3.22 | 1.07 | 18.65 | 12.65 | 20.14 | 14.14 |

| 1/2×9 | 2200 | 2.29 | 0.64 | 3.2 | 1.07 | 24.94 | 15.94 | 26.43 | 17.43 |

| 1/2×12 | 2200 | 2.71 | 0.64 | 3.2 | 1.07 | 30.94 | 18.94 | 32.43 | 20.43 |

| 5/8×6 | 3500 | 3.21 | 0.79 | 3.9 | 1.32 | 19.74 | 13.74 | 21.82 | 15.82 |

| 5/8×9 | 3500 | 3.95 | 0.79 | 3.89 | 1.32 | 26.08 | 17.08 | 28.16 | 19.16 |

| 5/8×12 | 3500 | 4.58 | 0.79 | 3.89 | 1.32 | 32.08 | 20.08 | 34.16 | 22.16 |

| 3/4×6 | 5200 | 4.8 | 0.97 | 4.71 | 1.52 | 21.09 | 15.09 | 23.68 | 17.68 |

| 3/4×9 | 5200 | 5.85 | 0.97 | 4.68 | 1.52 | 27.49 | 18.49 | 30.08 | 21.08 |

| 3/4×12 | 5200 | 6.72 | 0.97 | 4.68 | 1.52 | 33.49 | 21.49 | 36.08 | 24.08 |

| 3/4×18 | 5200 | 8.45 | 0.97 | 4.71 | 1.52 | 45.49 | 27.49 | 48.08 | 30.08 |

| 7/8×12 | 7200 | 9.37 | 1.16 | 5.5 | 1.77 | 34.65 | 22.65 | 37.62 | 25.62 |

| 7/8×18 | 7200 | 11.8 | 1.16 | 5.5 | 1.77 | 47.12 | 29.12 | 50.09 | 32.09 |

| 1×6 | 10000 | 10.4 | 1.34 | 6.09 | 2.05 | 23.82 | 17.82 | 27.18 | 21.18 |

| 1×12 | 10000 | 13.8 | 1.34 | 6.09 | 2.05 | 35.82 | 23.82 | 39.18 | 27.18 |

| 1×18 | 10000 | 17.1 | 1.34 | 6.09 | 2.05 | 47.82 | 29.82 | 51.18 | 33.18 |

| 1×24 | 10000 | 21 | 1.34 | 6.06 | 2.05 | 60.42 | 36.42 | 63.78 | 39.78 |

| 1-1/4×12 | 15200 | 21.9 | 1.84 | 8.09 | 2.82 | 39.37 | 27.37 | 43.58 | 31.58 |

| 1-1/4×18 | 15200 | 25.9 | 1.84 | 8.09 | 2.82 | 51.37 | 33.37 | 55.58 | 37.58 |

| 1-1/4×24 | 15200 | 29.8 | 1.84 | 8.09 | 2.82 | 63.93 | 39.93 | 68.14 | 44.14 |

| 1-1/2×12 | 21400 | 32.6 | 2.06 | 8.93 | 2.81 | 40.76 | 28.76 | 45.68 | 33.68 |

| 1-1/2×18 | 21400 | 38 | 2.06 | 8.93 | 2.81 | 52.76 | 34.76 | 57.68 | 39.68 |

| 1-1/2×24 | 21400 | 43.5 | 2.06 | 8.93 | 2.81 | 65.38 | 41.38 | 70.3 | 46.3 |

| 1-3/4×18 | 28000 | 53.5 | 2.6 | 9.36 | 3.35 | 53.35 | 35.35 | 59.16 | 41.16 |

| 1-3/4×24 | 28000 | 61.1 | 2.6 | 9.36 | 3.35 | 65.35 | 41.35 | 71.16 | 47.16 |

| 2×24 | 37000 | 96.3 | 2.62 | 11.8 | 3.74 | 69.64 | 45.64 | 76.72 | 52.72 |

| 2-1/2×24 | 60000 | 167 | 3.06 | 13.26 | 4.44 | 72.97 | 48.97 | 82.18 | 58.18 |

| 2-3/4×24 | 75000 | 199 | 3.69 | 14.92 | 4.19 | 74.75 | 50.75 | 85.5 | 61.5 |